Inspection and quality control of paint and sandblast

Metals are purely unstable, the natural tendency of these elements to oxidize and stabilize is a major problem today around the world. Huge expenses have been and will be spent on studies and researches in this field, and it is possible that unfortunate accidents have occurred due to corrosion and oxidation of metals.

Prepare the surface for paint stained

It is very important to clean the surface from rust and other contaminants such as grease, oil and dust before painting. If the best paint is used and applied in the best way, but the surface preparation is not good, the paint will disappear in a short time.

A variety of methods for the preparation of

(HAND CLEANING) 1- Hand cleaning

(WATER BLAST CLEANING) 2- Preparing the surface by spraying water with pressure

(SAND BLAST) 3- Preparing the surface by spraying sand with compressed air

(SHOT BLAST) 4- Preparing the surface by shot blast method

Surface preparation by throwing sand with intensive air ( (SAND BLAST

Sandblasting occurs for two important reasons:

A – to remove all surface contamination

B – rough surface to improve bonding primer matter how much sand and standard Air Pressure is over 7 times sandblasted surface rougher and adhesion would be more ideal. In this method, the compressed air production device (compressor) delivers the air to the sandblast boiler with a hose. From the sandblast boiler, the sand is placed in a controlled manner in the compressed air path and exits the outlet nozzle with pressure. If the outlet nozzle is taken towards the metal surface, it will clean and rough the surface. Before starting sandblasting, the metal surface should be inspected and oil contaminants cleaned with a thinner.

Those that are sandblasted to fashion in terms of their :

A: Compressed air must be completely dry and free of oil.

B: The size of the sand should be between 0.3 to 3 mm.

A: The sandblasted surface should be cleaned with good compressed air and free of dust.

D: The minimum roughness of the sandblasted surface should be 2 microns, which should be measured by a roughness tester.

coloring

Coating (paint): Basically, paint is a mixture that can meet our expectations for decoration and surface protection. Excellent coating is generally obtained by mixing materials called resin (RESIN), solvent pigment ( SOLVENT ), and additives (ADDITIVES) . The main base of the paint is resin. Resin has major functions. Creating an impermeable film on the desired surface is one of the most important tasks of the resin, another task of the resin is adhesion to the surface. The cleaner the metal surface, the greater the chemical and polar adhesion, and the rougher the steel surface, the higher the mechanical adhesion of the resin.

The effect of atmospheric conditions on the quality of paint application

1- If the paint is applied in stormy weather, the following things will happen.

A. Paint surfaces that have not yet dried become contaminated with dust.

B – dust on surfaces that are stained by the end of the meeting and the lack of adhesion in color.

C – dust on imported container and nozzle clogging due to waterborne paint.

2- Painting in rainy weather does not stick to the previous layer and separates from the surface.

Methods of color staining

2- Painting with a brush

2- Painting with hand roller

3- Immersion painting

3- Painting with spray machine (pistol)

2- Airless spraying (AIR LESS)

Of transport and forwarding pieces painted by

2- The drying time of the paint film is determined by the manufacturer.

2- Inorganic woven tow ropes should be used for moving, loading and unloading painted parts.

3- Painted parts should be placed on wooden parts in any situation.

Inspection

Inspection and quality control of paint

3. All inspections must be carried out by the inspector in accordance with the following conditions:

A. The inspector should check the requirements before sandblasting, such as grinding pimples and sharp edges, removing grease contaminants, etc. from the surface.

B- Recognize the characteristics and quality of surface preparation and control the surface preparation and painting with special tools.

C- Control the techniques of color application and the properties of different colors

3- If the quality of surface preparation is desirable. The surface temperature should not be higher than 2 ° C and the weather conditions should be favorable. The inspector orders the paint to be mixed.

2- Check the expiration date of the paint.

2- Paint cans should be inspected after opening to ensure their proper quality.

A variety of paint adhesion testing methods

In this section, we talk about the implementation method and criteria for accepting common paint adhesion tests in the country’s industry, namely X-cut (X-CUT) and cross-cut (CROSS-CUT) according to ASTM D 3359 in a simple and practical way.

In general, there are three main methods for determining the adhesion of paint, which are:

Test method (X-Cut) :

To perform the adhesion test (cross cut), a surface should be selected that is free of scratches and scratches.

Make sure the surface is clean and dry. High temperature and high humidity affect the adhesion of the film. Make two cuts approximately 1.5 inches (40 mm) long at the desired level so that they pass through each other so that the angle between them is 30 to 45 degrees.

Examine the cuts and crevices for light reflections from the metal surface to make sure that the paint coating film is fully penetrated. You should note that if the metal surface is not visible, create another new X cut in another location.

Note: The cutting operation must be done in one step and it is not correct to deepen the previous gap.

Peel off two rounds of adhesive tape and cut a 3-inch (75 mm) piece out of it.

Place the middle of the glue at the point of intersection of the cuts and then stick it on the cut with your finger and stick it completely on the surface.

After applying 90 x 30 seconds of glue, quickly remove the tape from the surface. This should be done without further shaking of the hand and also the tape should have a 180 degree angle on itself when digging.

Now examine the X-spot for separation from the metal surface using the scales below:

5A: No separation

4A: Slight biting or separation along the cuts or at the point of collision

3A: Rough and cut separation along the cuts up to 1.6 mm on the other side

2A: Rough and cut separation along most Cuts up to 3.2 mm on the other side

1A: Separation in most areas of the X cut in the underside

0A: Separation farther from the X area

Repeat the test in sufficient numbers elsewhere on the surface to ensure that other areas are adhered.

Method : Pull Off

In this method, we first glue a thin plate called Dolly to the surface of the tested paint.

Then we attach the adhesion test device by Pull Off Testing method to this plate and enter the upward force by turning the lever on the plate.

Add enough force so that the plate is completely separated from the base surface by the underlying layer of paint. At this time, the amount of force entering the page at the last moment will be the criterion of our calculations.

Test Cross-Cut (CROSS-CUT) :

Using a cross-cut tool, create two cross-sections of approximately 20 mm in length on the color film. The cut should be such that in the very first time, the color film is cut and reaches the metal surface. These cuts can also be made using a sharp razor without a cross-cutting tool. In this case, for paints up to a thickness of 50 microns, we create 11 cuts with a distance of one millimeter from each other, and for paints from a thickness of 50 to 125 microns, we create 6 cuts with a distance of 2 millimeters from each other.

Using a soft brush, clean the mesh cuts.

Peel off two complete strips of adhesive tape and cut a 75 mm piece of it.

Place the middle of the glue at the intersection of the cuts and glue the two sides to the smaller angle of the intersection. Then rub it with an eraser until it sticks completely to the surface.

After 30.90 seconds, apply the adhesive quickly and without further shaking.

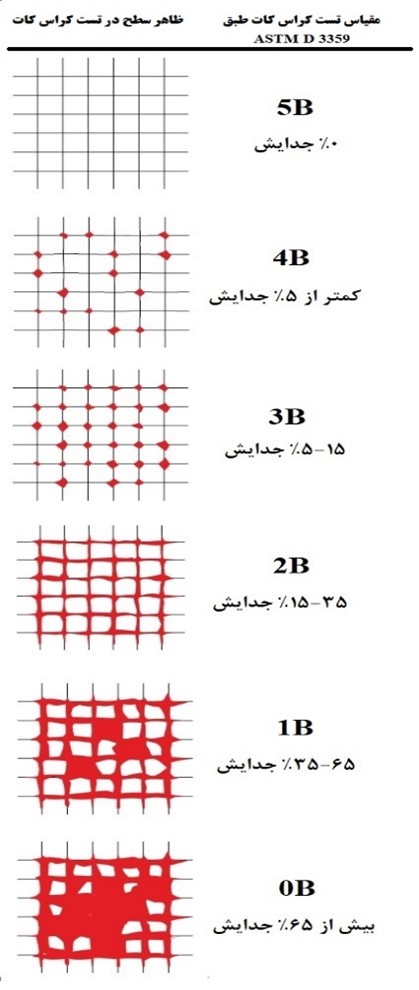

Inspect the cut site for separation of paint from the metal surface using the classification shown below for the amount of separation in the cross-cut test. The acceptance criteria for the adhesion test are specified in the project spec. In most projects, the acceptance criteria are 4B and 5B.

Inspection and quality control of paint and sandblast

Metals are purely unstable, the natural tendency of these elements to oxidize and stabilize is a major problem today around the world. Huge expenses have been and will be spent on studies and researches in this field, and it is possible that unfortunate accidents have occurred due to corrosion and oxidation of metals.

Prepare the surface for paint stained

It is very important to clean the surface from rust and other contaminants such as grease, oil and dust before painting. If the best paint is used and applied in the best way, but the surface preparation is not good, the paint will disappear in a short time.

A variety of methods for the preparation of

(HAND CLEANING) 1- Hand cleaning

(WATER BLAST CLEANING) 2- Preparing the surface by spraying water with pressure

(SAND BLAST) 3- Preparing the surface by spraying sand with compressed air

(SHOT BLAST) 4- Preparing the surface by shot blast method

Surface preparation by throwing sand with intensive air ( (SAND BLAST

Sandblasting occurs for two important reasons:

A – to remove all surface contamination

B – rough surface to improve bonding primer matter how much sand and standard Air Pressure is over 7 times sandblasted surface rougher and adhesion would be more ideal. In this method, the compressed air production device (compressor) delivers the air to the sandblast boiler with a hose. From the sandblast boiler, the sand is placed in a controlled manner in the compressed air path and exits the outlet nozzle with pressure. If the outlet nozzle is taken towards the metal surface, it will clean and rough the surface. Before starting sandblasting, the metal surface should be inspected and oil contaminants cleaned with a thinner.

Those that are sandblasted to fashion in terms of their :

A: Compressed air must be completely dry and free of oil.

B: The size of the sand should be between 0.3 to 3 mm.

A: The sandblasted surface should be cleaned with good compressed air and free of dust.

D: The minimum roughness of the sandblasted surface should be 2 microns, which should be measured by a roughness tester.

coloring

Coating (paint): Basically, paint is a mixture that can meet our expectations for decoration and surface protection. Excellent coating is generally obtained by mixing materials called resin (RESIN), solvent pigment ( SOLVENT ), and additives (ADDITIVES) . The main base of the paint is resin. Resin has major functions. Creating an impermeable film on the desired surface is one of the most important tasks of the resin, another task of the resin is adhesion to the surface. The cleaner the metal surface, the greater the chemical and polar adhesion, and the rougher the steel surface, the higher the mechanical adhesion of the resin.

The effect of atmospheric conditions on the quality of paint application

1- If the paint is applied in stormy weather, the following things will happen.

A. Paint surfaces that have not yet dried become contaminated with dust.

B – dust on surfaces that are stained by the end of the meeting and the lack of adhesion in color.

C – dust on imported container and nozzle clogging due to waterborne paint.

2- Painting in rainy weather does not stick to the previous layer and separates from the surface.

Methods of color staining

2- Painting with a brush

2- Painting with hand roller

3- Immersion painting

3- Painting with spray machine (pistol)

2- Airless spraying (AIR LESS)

Of transport and forwarding pieces painted by

2- The drying time of the paint film is determined by the manufacturer.

2- Inorganic woven tow ropes should be used for moving, loading and unloading painted parts.

3- Painted parts should be placed on wooden parts in any situation.

Inspection

Inspection and quality control of paint

3. All inspections must be carried out by the inspector in accordance with the following conditions:

A. The inspector should check the requirements before sandblasting, such as grinding pimples and sharp edges, removing grease contaminants, etc. from the surface.

B- Recognize the characteristics and quality of surface preparation and control the surface preparation and painting with special tools.

C- Control the techniques of color application and the properties of different colors

3- If the quality of surface preparation is desirable. The surface temperature should not be higher than 2 ° C and the weather conditions should be favorable. The inspector orders the paint to be mixed.

2- Check the expiration date of the paint.

2- Paint cans should be inspected after opening to ensure their proper quality.

A variety of paint adhesion testing methods

In this section, we talk about the implementation method and criteria for accepting common paint adhesion tests in the country’s industry, namely X-cut (X-CUT) and cross-cut (CROSS-CUT) according to ASTM D 3359 in a simple and practical way.

In general, there are three main methods for determining the adhesion of paint, which are:

Test method (X-Cut) :

To perform the adhesion test (cross cut), a surface should be selected that is free of scratches and scratches.

Make sure the surface is clean and dry. High temperature and high humidity affect the adhesion of the film. Make two cuts approximately 1.5 inches (40 mm) long at the desired level so that they pass through each other so that the angle between them is 30 to 45 degrees.

Examine the cuts and crevices for light reflections from the metal surface to make sure that the paint coating film is fully penetrated. You should note that if the metal surface is not visible, create another new X cut in another location.

Note: The cutting operation must be done in one step and it is not correct to deepen the previous gap.

Peel off two rounds of adhesive tape and cut a 3-inch (75 mm) piece out of it.

Place the middle of the glue at the point of intersection of the cuts and then stick it on the cut with your finger and stick it completely on the surface.

After applying 90 x 30 seconds of glue, quickly remove the tape from the surface. This should be done without further shaking of the hand and also the tape should have a 180 degree angle on itself when digging.

Now examine the X-spot for separation from the metal surface using the scales below:

5A: No separation

4A: Slight biting or separation along the cuts or at the point of collision

3A: Rough and cut separation along the cuts up to 1.6 mm on the other side

2A: Rough and cut separation along most Cuts up to 3.2 mm on the other side

1A: Separation in most areas of the X cut in the underside

0A: Separation farther from the X area

Repeat the test in sufficient numbers elsewhere on the surface to ensure that other areas are adhered.

Method : Pull Off

In this method, we first glue a thin plate called Dolly to the surface of the tested paint.

Then we attach the adhesion test device by Pull Off Testing method to this plate and enter the upward force by turning the lever on the plate.

Add enough force so that the plate is completely separated from the base surface by the underlying layer of paint. At this time, the amount of force entering the page at the last moment will be the criterion of our calculations.

CROSS-CUT test:

Using a cross-cut tool, create two cross-sections of approximately 20 mm in length on the color film. The cut should be such that in the very first time, the color film is cut and reaches the metal surface. These cuts can also be made using a sharp razor without a cross-cutting tool. In this case, for paints up to a thickness of 50 microns, we create 11 cuts with a distance of one millimeter from each other, and for paints from a thickness of 50 to 125 microns, we create 6 cuts with a distance of 2 millimeters from each other.

Using a soft brush, clean the mesh cuts.

Peel off two complete strips of adhesive tape and cut a 75 mm piece of it.

Place the middle of the glue at the intersection of the cuts and glue the two sides to the smaller angle of the intersection. Then rub it with an eraser until it sticks completely to the surface.

After 30.90 seconds, apply the adhesive quickly and without further shaking.

Inspect the cut site for separation of paint from the metal surface using the classification shown below for the amount of separation in the cross-cut test. The acceptance criteria for the adhesion test are specified in the project spec. In most projects, the acceptance criteria are 4B and 5B.